Engineering Office Phase

QUART's first development projects were managed under the umbrella of a privately owned and managed engineering office.

Our first product releases included technical OEM test phantoms and x-ray meters featuring solid-state detection technology, independently developed for customers in the medical imaging industry.

First Product Release: Integrator I

For diagnostic x-ray measurements, the Integrator I was the major step forward in the x-ray meter industry. The world-wide first application of solid-state technology in QUART‘s x-ray detectors, instead of utilising ionisation chambers, changed the characteristics of x-ray test equipment considerably.

Once bulky and heavy, meters could now be easily handled and transported. And the equipment's economic price point enabled the introduction of a national quality assurance programme in Germany for every level of x-ray imaging appliance.

The QUART dido Meter Is Born

The QUART Integrator II, one year later (1984) renamed to QUART dido, became the conceptual base of all future QUART meters.

The dido was the first PTB* approved diagnostic dosemeter of its kind - featuring solid-state detector technology. Equipped with a slanted display for better reading from a distance or from above, the QUART dido set a new standard for shape and design of x-ray QA testing devices already at that time.

*PTB = Physikalisch-Technische Bundesanstalt in Braunschweig / Germany, the national admission authority for x-ray meters

QUART X-Ray Image Quality Test Phantom

The introduction of x-ray image quality assurance standards in the 1980s required the development of comprehensive but easy-to-use tools.

Thanks to QUART’s expertise and resources, a new generation of technical x-ray QA phantoms was available from

the beginning of the process. The QUART SPecono and SPvario marked the starting point of this evolution.

Spin-Off As Incorporated Company

The increasing demand for innovative solutions for medical imaging QA by the industry and the successful addition of enhanced production capabilities lead to the incorporation of the business.

In 1986, QUART was established as an independent private company which has specialised in the design and manufacturing of x-ray QA products. We have been serving the industry under this brand ever since. Family-owned and driven by innovation.

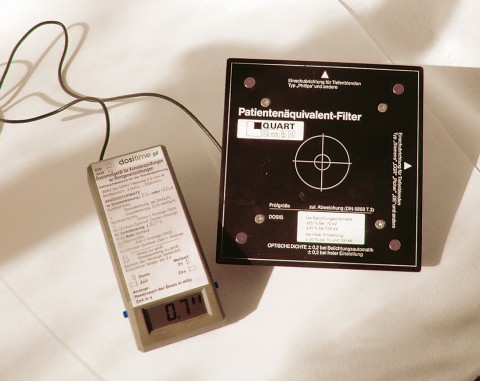

The Next-Generation QUART dido X-Ray Meter

Some time after its launch, the QUART dido x-ray meter was further diversified to become the first sandwich/double dosimeter. It could be used to measure dose before and after patient-equivalent filtration in constancy tests – in only one x-ray exposure.

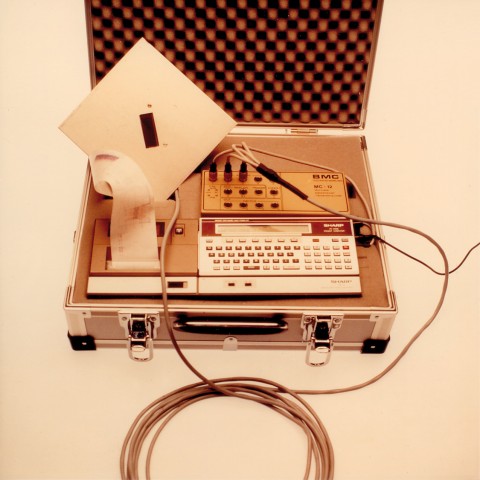

The QUART DAVID System

The DAVID system for the first time featured a compact laptop computer as a waveform analysis tool inclusive a print-out function to replace oscilloscopes previously used.

Designed as a sophisticated and complete measurement system, it was the perfect tool for service experts and state radiation

inspectors. After its launch it gained a reputation for causing a “toolbox revolution” in x-ray quality control.

The system name DAVID transcribes as „Digital Analyser for High-Voltage, Inherent Filtration and Dose Rate“.

Dental Imaging Test Phantom

The development of image quality test phantoms was launched quickly after the dental x-ray industry started inquiring for respective solutions. Until today, the general design features of QUART‘s dentFS and dent/digitest phantoms are still part of the DIN & IEC standard for dental image quality control.

Similarly to the general radiography test phantoms, the dental test phantoms provide all required image quality information from only one exposure.

Digital Subtraction Angiography Image Quality Phantom

The introduction of QUART‘s DSA phantom featuring longitudinal sliding technology has enabled a precise way to assess the imaging quality of subtraction angiography equipment. Although a bit bigger in size than other DSA phantoms, the QUART phantom offers technical and methodical advantages that cannot be met by other solutions in the market.

Although it was introduced some time ago, the phantom is still up-to-date and widely used. With a dedicated QUART-developed digital protocol, the test images can be evaluated using the latest information technologies.

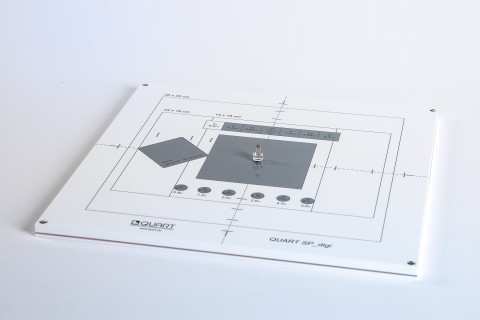

Digital Radiography and Fluoroscopy Test Phantom

The transformation from conventional to digital x-ray required a new approach on technology for x-ray QA. The QUART-developed and standardised SPdigi phantom has been encorporating test objects to specifically assess image quality

of digital x-ray equipment.

The design of our SPdigi phantom is widely used all over the world today.

QUART dido2000K and dido2100K

The dido2000K/2100K series dosimeters are all-in-one instruments that incorporate kV and dose next to time, pulse and dose rate measurement. With their optional feature to output data via USB interface, they further enabled waveform analysis and protocol print-outs.

These meters are still widely used, and they will be serviced and calibrated by QUART until further notice.

Unique Cone-Beam CT Phantom and Software

The combination of phantom and software to exclusively analyse digital parameters, such as Nyquist Frequency, Modulation Transfer Function and Contrast-to-Noise Ratio as measures of image quality, introduced a whole new concept into x-ray QA/QC. The QUART-developed algorithms and software automatically evaluate phantom images and so objectively assess the imaging performance of CBCT x-ray systems.

The later DIN and IEC standardised methodology were yet again based on our innovative contribution. The whole process is now establishing a unique benchmark as how to digitise x-ray QA/QC.

QUART didoNEO X-Ray Meters

The new didoNEO continues to advance the role that genuine technology plays in latest measurement applications. It expands user capabilities, maximises efficiency, increases flexibility and thus improves quality control and service workflow.

The system was first presented in 2012.